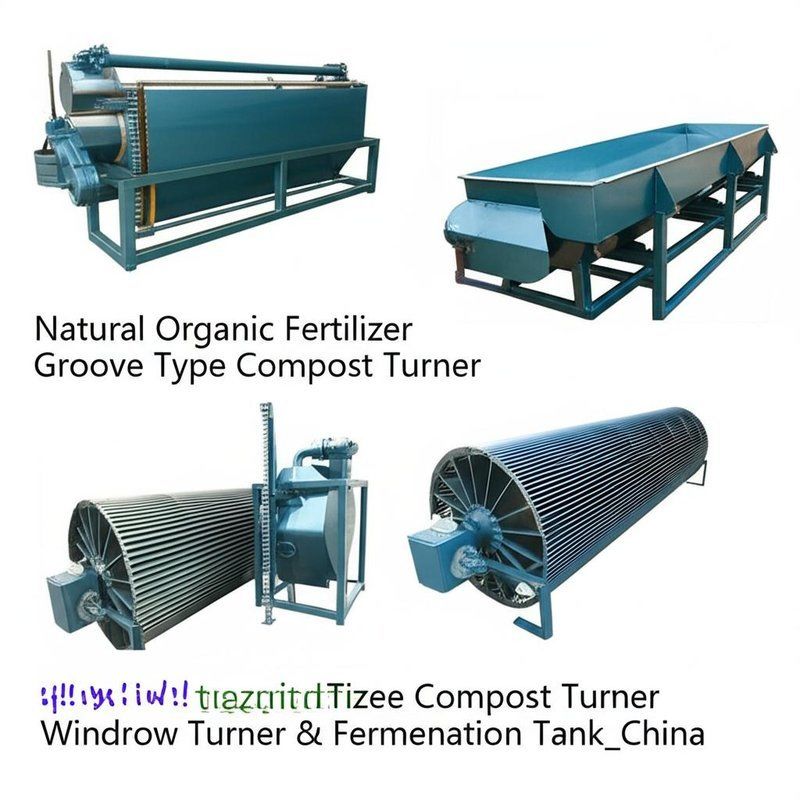

Our company mainly produces and sells the following types of natural organic fertilizer composting equipment: rotary blade trough type , beam wheel disc type , crawler type turner , and heated aerated fermentation tank. These composting equipment are all used for organic fertilizer composting and are commonly used in the fields of composting fermentation, decomposition , and garbage disposal. However, the core function of all three is to achieve material ventilation, temperature control, and decomposition through turning. However, the three have their own characteristics and differences in structural design, application scenarios, and performance characteristics . As shown in the figure below: Composting machine model -

1. The structure and operation mode of composting machine

have different main "turning mechanisms" and "movement methods" . Different structures and working modes directly determine the operating efficiency, applicable material status and site requirements, as shown in the following table :

|

Comparison Dimension

|

Rotary knife type trough turning machine

|

Beam wheel type turning machine

|

Crawler-type turner

|

|

Main structure

|

Fixed trough + rotating blade teeth (multiple sets) + track travel

|

Large beam frame + wheel type flip gear + track/tire movement

|

Track chassis (imitation engineering machinery) + suspended rotating blade teeth (multiple sets)

|

|

Work site

|

Pre-installed concrete/steel structure fermentation tank (fixed) , generally indoor

|

Preset wide fermentation tank or large fermentation area (semi-fixed) , generally indoor

|

No preset site requirements ( fixed ground level, can be outdoors if no environmental protection requirements are met )

|

|

Movement

|

Travel back and forth along the trough track (one-way/two-way)

|

Move in a straight line along the fermentation area track or tires

|

Tracked all-terrain travel (able to turn and climb)

|

|

Turning depth

|

Shallow (0.8-2 m , depending on the trough depth)

|

Deeper ( 0.8-2.5m , adjustable crossbeam)

|

Medium (0.6-1.5 m , varies with chassis height)

|

|

Turning width

|

Generally 3-6 meters

|

Generally 6-30 meters

|

Generally 2.5-4.5 meters

|

|

Material adaptability

|

The materials processed by the three types of composting machines are basically the same, with no difference. Common materials include livestock manure, straw , sludge, restaurant waste, and semi-finished compost .

|

2. Selection of composting equipment

Step 1: Clarify core needs — first determine “scenario priority”

• If the demand is "large-scale, standardized production" (such as an organic fertilizer plant with a daily output of more than 100 tons): the rotary knife-type trough turner is preferred . It is suitable for fixed production lines. Automation + high efficiency can reduce labor costs.

• If the requirement is to process difficult materials (such as municipal sludge and restaurant waste with high moisture content/high viscosity/requiring deep turning): a large-beam wheel-type turner is a must-choose. Its strong crushing and deep turning capabilities prevent material corruption and ensure composting quality.

• If the requirement is "flexible operation and no fixed site" (such as small and medium-sized farms, fermentation in multiple sites in rotation): the first choice is a crawler-type tiller, which does not require site modification, has strong maneuverability, and is suitable for small-batch and high-frequency operations.

Step 2: Match key parameters – Avoid “over- or under-performance”

1. Processing capacity : select according to the daily material volume (e.g. crawler type for daily processing below 50 tons, rotary cutter type for 50-200 tons, beam wheel type for processing above 200 tons);

2. Site conditions :

◦ There is a fixed workshop/can build a tank → rotary cutter tank type;

◦ Need guide rail wall → beam wheel type;

◦ No workshop required, ground level → crawler type;

3. Budget range : Generally, the following are: beam wheel type (100,000-300,000 RMB) > cutter groove type (50,000-200,000 RMB) > crawler type (30,000-150,000 RMB). A comprehensive assessment should be made based on the subsequent maintenance costs (for example, crawler tracks are easily damaged, so replacement costs need to be considered for long-term use).

Step 3: Consider long-term adaptation – leaving room for expansion

• If you plan to expand production capacity in the future: the rotary cutter trough type can be expanded by "increasing the number of troughs", the beam wheel type can replace the beam with a larger span, and the crawler type requires additional equipment and advance site/circuit planning;

• If it is necessary to connect to subsequent processes (such as screening and packaging): the rotary trough type can be seamlessly connected to the production line, while the crawler type requires manual material transfer, and the demand for automated connection needs must be weighed.

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!  Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!